- Stellantis upgraded its wind tunnel to the tune of $29.5 million

- The upgrades focused on aero efficiency to help with EV range

- What used to take hours can now take minutes to change with the recent wind tunnel upgrades

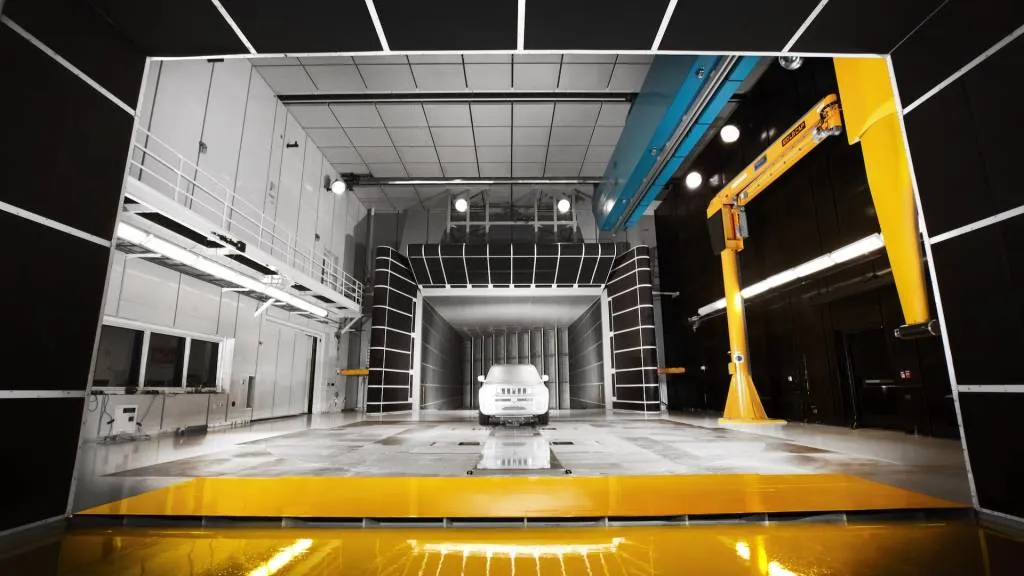

Stellantis on Wednesday unveiled a $29.5 million upgrade of the wind tunnel at its main research and development facility in Auburn Hills, Michigan, giving engineers an enhanced tool to further improve efficiency and EV range.

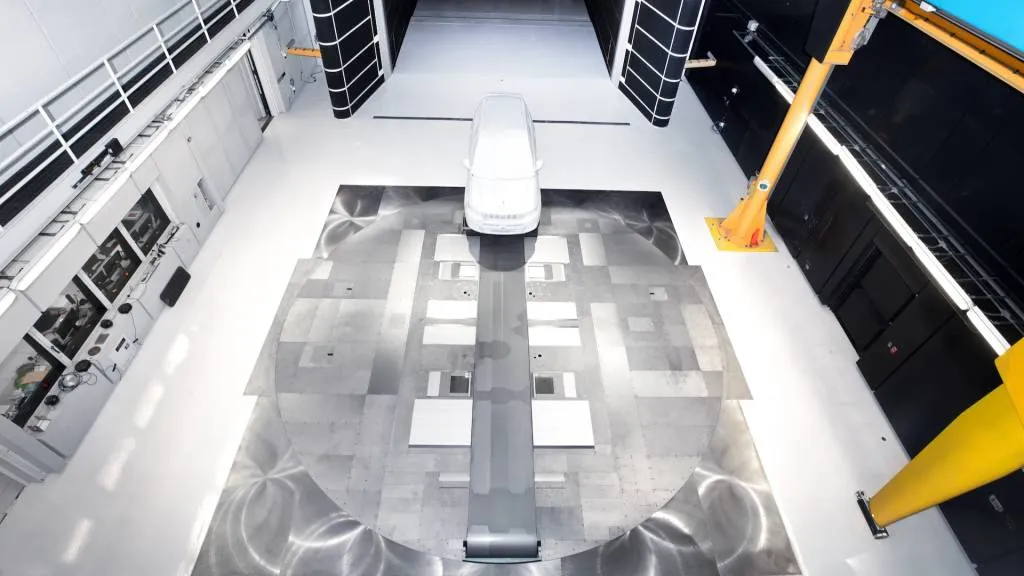

Upgrades to the wind tunnel, which has been in continuous operation since 2002, include provisions for specific measurements of airflow resistance around wheels and tires, Stellantis said, adding that wheels and tires can account for up to 10% of real-world aerodynamic drag.

Vehicles remain static, with belts suspended on cushions of air turning all four wheels. A fifth moving belt represents the effect of travel over a road surface. Compressed air drives the belts at speeds up to 140 mph, while the tunnel is capable of generating wind speeds of up to 160 mph, according to Stellantis. The automaker uses similar wind-tunnel technology at other facilities globally, but the Michigan facility can accommodate larger vehicles—including EVs based on the STLA Large and STLA Frame platforms.

Stellantis wind tunnel in Auburn Hills, Michigan

Increased automation also means that changes of wheelbase and track that can take up to two hours in conventional wind tunnels can now be done in minutes, according to Stellantis. This lets the wind tunnel continue to act as a vital complement to virtual simulations.

“This apparatus is a great addition to virtual tools, which may not account for factors such as tire deformation that can compromise aerodynamics,” Mark Champine, head of Stellantis’ North American engineering technical centers, said in a statement. “With this technology we can replicate such conditions and capture real-time data to explore solutions.”

The wind tunnel is part of an estimated $85 million commitment to facility upgrades specified in a 2019 Stellantis contract with the UAW. However, the automaker is also reportedly looking to sell its Arizona proving grounds.

Stellantis wind tunnel in Auburn Hills, Michigan

The need to maximize EV range without further growing battery-pack sizes has revived a century-old obsession with aerodynamics—one that Stellantis is familiar with. The Chrysler Airflow debuted in 1934 with wind-tunnel-tested styling that proved controversial at the time. The Airflow name was revived in 2022 for an electric SUV concept, although it’s still unclear whether that vehicle or a next-generation minivan will be the Chrysler brand’s first EV.

Also of aerodynamic note is the 2024 Dodge Charger Daytona, based on the STLA Large platform and also being used to test solid-state batteries. The electric muscle car uses an innovative front airfoil to reconcile the blunt front end reminiscent of the classic 1968 Charger with modern aero requirements. The Daytona name, which denotes all-electric models, also references the Charger Daytona race car, which used a pointed nose cone and tall rear wing to minimize aerodynamic drag on NASCAR oval tracks.

Stellantis is targeting 50% U.S. EV sales and 100% European EV sales by 2030, with 75 models globally by that time.