Stellantis on Thursday announced an agreement with Texas-based Zeta Energy to develop lithium-sulfur batteries that could significantly reduce cost and pack weight, while boosting charging speed.

The automaker and Zeta Energy claim lithium-sulfur chemistry can deliver comparable volumetric energy density to current lithium-ion battery cells, but at less than half the price per kwh. Sulfur is cheap and widely available, Stellantis noted in a press release, adding that batteries will be produced using unrefined sulfur produced as a byproduct of other industries, other waste materials, methane, helping to keep costs down while minimizing carbon dioxide emissions.

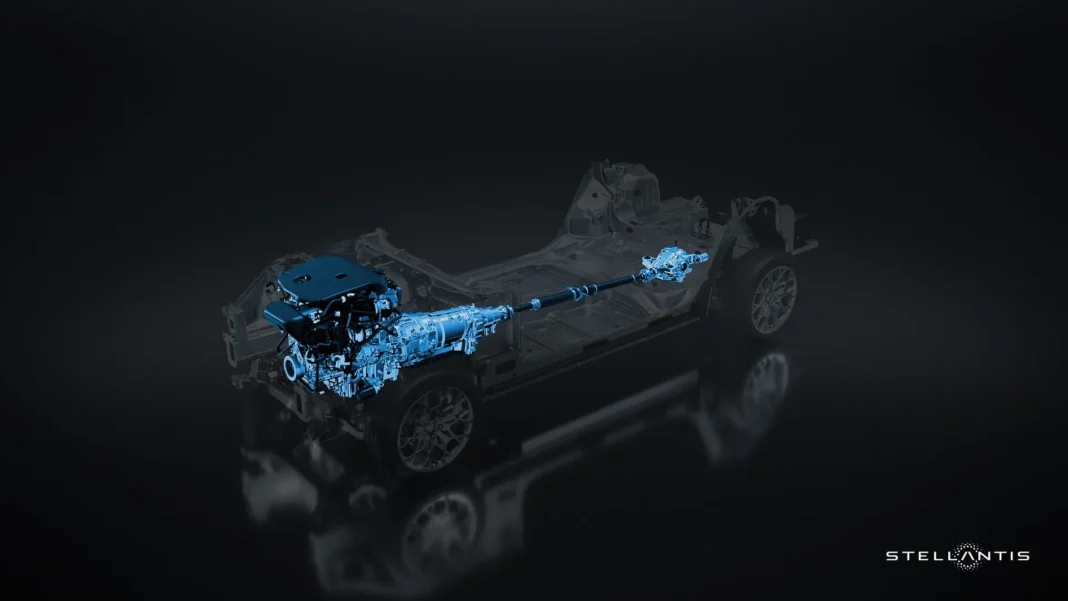

STLA Large platform

Lithium-sulfur tech also “has the potential” to increase fast-charging speeds by up to 50%, the automaker emphasized, along with significantly lighter battery packs with the same usable capacity as equivalent lithium-ion packs.

The agreement calls for pre-production development work with an eye toward possible commercialization by 2030. Stellantis intends to use existing battery factories, and claims it can keep the supply chain for battery materials concentrated within either Europe or North America, in line with its current vehicle manufacturing footprint.

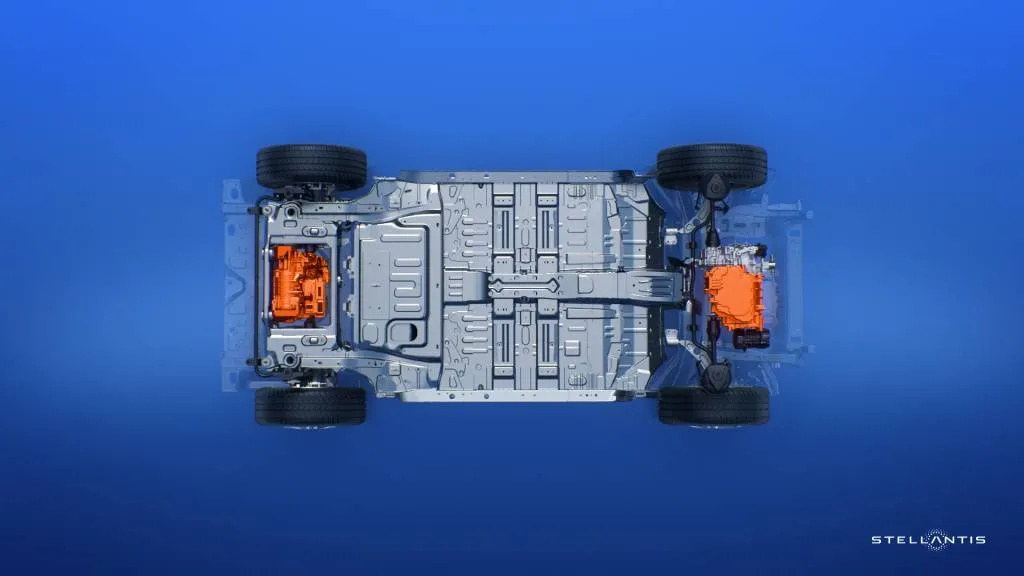

Stellantis STLA Medium platform

Stellantis in 2023 announced a partnership with Lyten to develop lithium-sulfur battery tech, as well as an investment in the California-based startup from its Stellantis Ventures arm. The automaker made clear to Green Car Reports that this partnership with Zeta Energy is complementary to the partnership with Lyten.

For years, lithium-sulfur batteries have been considered one of the next frontiers to greatly boost range without adding weight or driving up production cost. Advances from the past decade have helped push development past some of the key obstacles, but mass production and relatively short life for the cells have remained issues. It will be interesting to see if Stellantis can address those issues before the end of the decade.