As EVs continue to reshape the transportation industry, understanding the journey of an EV battery—from its creation to its eventual recycling—has never been more important.

The life cycle of these batteries is a complex, multi-stage process, and every phase holds opportunities to reduce environmental impact, maximize efficiency, and extend the value of these essential components. EV Battery Solutions by Cox Automotive plays a vital role in this ecosystem, working to keep batteries in use for as long as possible and ensuring they are properly recycled when their useful life comes to an end.

1. Manufacturing: The Birth of an EV Battery

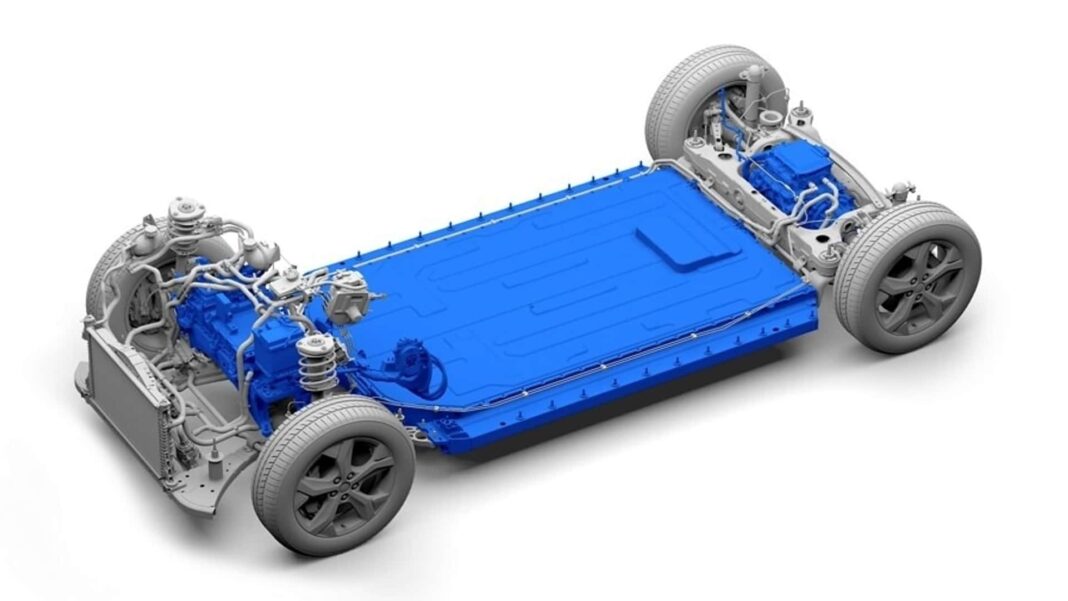

The life of an EV battery begins with the sourcing of raw materials such as lithium, nickel, cobalt, and graphite. These materials are extracted, refined, and used to produce battery cells, which are then assembled into modules and packs.

This initial phase is energy-intensive and relies heavily on the availability of natural resources. Reducing the environmental footprint at this stage is crucial, and innovations in sustainable sourcing and production are helping to improve this process.

2. Usage: Maximizing Performance and Longevity

The performance of a battery is affected by factors such as charging habits, driving conditions, and the climate. Over time, even with the best maintenance, a battery’s capacity to hold a charge diminishes.

EVBS offers diagnostic tools and repair services that help extend battery life. Through regular maintenance and intelligent monitoring, EVBS can help EV owners and fleet operators maintain optimal battery performance, delaying the need for costly replacements.

3. End of Life: The Importance of Recycling

Eventually, even the most well-maintained battery reaches the end of its operational life. This is where EV Battery Solutions’ recycling efforts come into play. Rather than allowing old batteries to become hazardous waste, EVBS helps ensure that valuable materials are recovered and repurposed.

The EVBS recycling process is designed to minimize environmental harm by recovering critical elements like lithium, cobalt, and nickel. These materials are then reintegrated into the supply chain, reducing the need for new mining operations and cutting down on the carbon footprint associated with material extraction. By promoting a circular economy, EVBS contributes to reducing the overall environmental impact of electric vehicles.

Transporting recovered recycling materials before they undergo shredding is the first step in producing Black Mass—critical for extracting valuable elements like lithium and nickel for reuse in new EV batteries.

4. Environmental Benefits: A Sustainable Future

One of the key outcomes of the recycling process is the recovery of valuable materials, such as lithium, cobalt, nickel, and manganese, that are essential for manufacturing new EV batteries. By recovering and reusing these materials through Black Mass processing, EVBS significantly reduces the need for additional mining of raw materials, which minimizes the environmental and social impact associated with resource extraction.

Dry recycling efforts, used by EVBS, also help prevent harmful chemicals from leaking into the environment, lowering the carbon footprint of EVs even further.

The author of this article, Bryce Cornet, is Senior Manager of EV Supply Chain Logistics at Spiers New Technologies Inc (SNT), a Cox Automotive Company.